A Guide to Insulated Metal Panels for PEMB Projects

Insulated metal panels are an excellent choice for Pre-Engineered Metal Building (PEMB) projects. These panels are popular because they offer great benefits like energy efficiency, durability, and aesthetic appeal. They help keep buildings warm in the winter and cool in the summer, saving on energy costs. This is especially important for large buildings where heating and cooling can get expensive

Structurally, these panels are strong and long-lasting. They stand up to various weather conditions, making them perfect for projects across the United States.

They can withstand wind, rain, and even some impacts, ensuring your building stays in good shape for years. Their strength makes them a reliable choice for many types of buildings, from warehouses to schools.

Another reason people choose insulated metal panels is their look. They come in different styles and colors, allowing you to customize the appearance of your building.

A well-designed exterior can make a big difference, attracting attention and improving the building's overall value. With all these benefits, it's easy to see why insulated metal panels are a smart choice for your next PEMB project.

Benefits of Using Insulated Metal Panels

Energy Efficiency

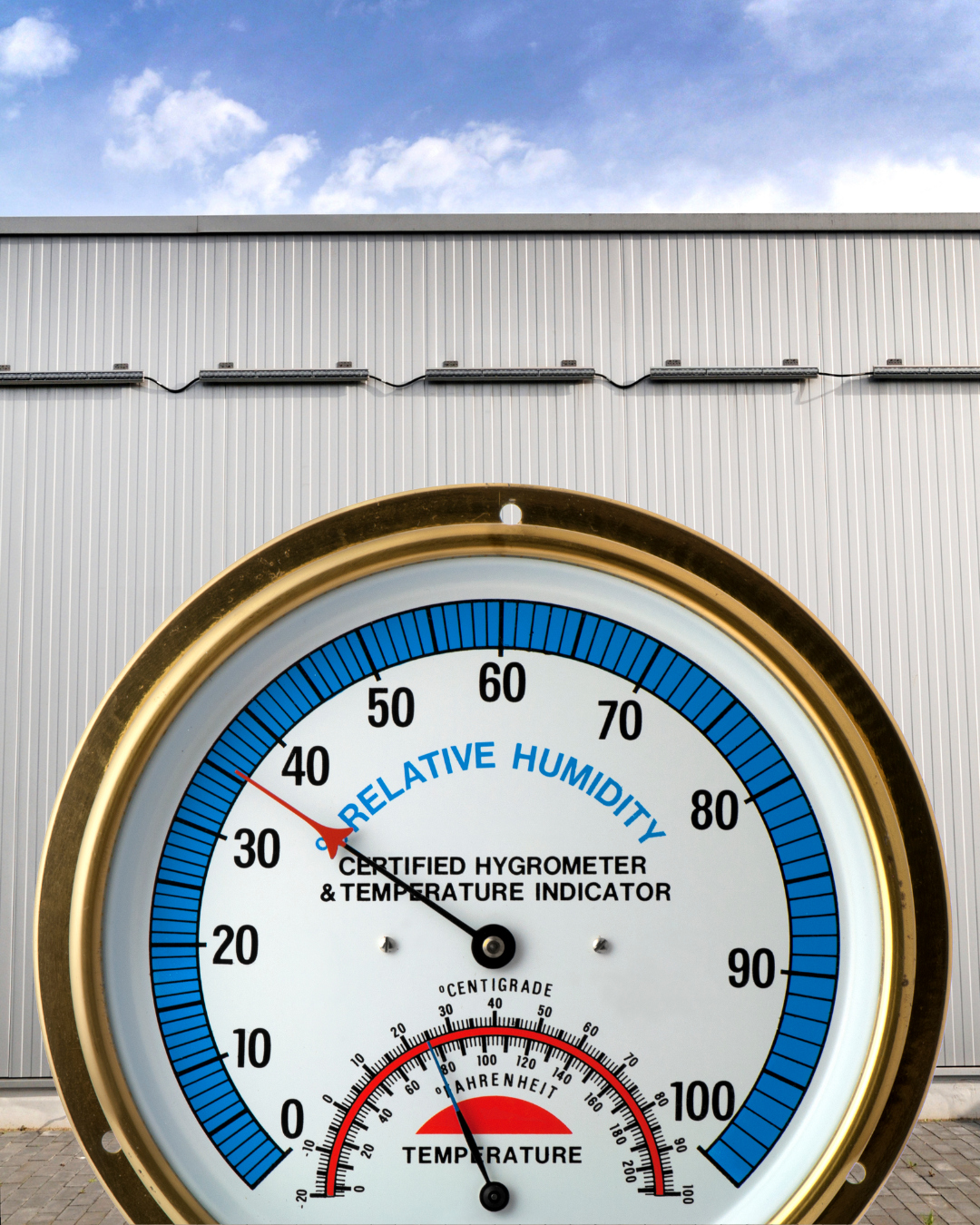

Insulated metal panels are highly energy-efficient. They have built-in insulation that helps regulate temperature inside the building. This means less need for heating in the winter and cooling in the summer, which can save a lot on energy bills. The panels keep the indoor climate stable, making the building more comfortable for occupants.

Durability and Strength

These panels are known for their durability and strength. Made from tough materials, they can resist strong winds, heavy rains, and even impacts. This makes them ideal for various climates and locations. They also have a long lifespan, meaning fewer repairs and replacements. This durability can reduce long-term maintenance costs and provide peace of mind.

Aesthetic Appeal

Insulated metal panels also offer aesthetic benefits. They come in different styles, colors, and finishes, allowing for customization. This means you can match the building's exterior to your specific preferences or brand colors. A good-looking building can attract more attention and potentially increase its value. This makes insulated metal panels a versatile option for many types of projects.

Types of Insulated Metal Panels

Polyurethane Panels

Polyurethane panels are a popular choice for insulation. They provide high thermal resistance, meaning they are excellent at keeping heat in or out. These panels are lightweight yet strong, making them easy to install. They are often used in commercial buildings, schools, and other large structures where energy efficiency is crucial.

Polystyrene Panels

Polystyrene panels are another type of insulated metal panel. They are cost-effective and offer good insulation properties. These panels are less dense than polyurethane, making them lighter and easier to handle. They are a great option for those looking for an affordable yet efficient insulation solution. They also perform well in a variety of weather conditions.

Mineral Wool Panels

Mineral wool panels are known for their fire-resistant properties. Made from natural rock and slag, they can withstand high temperatures. This makes them an excellent choice for buildings requiring extra fire safety measures.

They also provide good thermal and acoustic insulation, making them versatile for various applications. These panels are often used in schools, hospitals, and other buildings where safety is a top concern.

Installation Process for Insulated Metal Panels

Preparing the Site

Before installing insulated metal panels, start by preparing the site. Clear the area of any debris and obstacles to ensure a smooth installation process. Check that the foundation is stable and level to support the panels properly. Proper site preparation helps avoid problems during and after installation, ensuring the panels perform at their best.

Installing the Panels

The next step is installing the panels. Begin by placing the panels in their designated spots, aligning them correctly. Use appropriate fasteners and tools to secure each panel firmly in place.

Make sure to follow manufacturer guidelines for spacing and attachment to get the best results. This step requires precision to ensure the panels fit together well and provide a seamless barrier.

Sealing and Finishing Touches

Once the panels are installed, focus on sealing and finishing touches. Apply sealants to the joints and edges to prevent air and water leaks. This step is vital for maintaining the panels' insulating properties.

Check that all panels are securely attached and make any necessary adjustments. Completing these finishing touches will enhance the overall performance and appearance of the insulated metal panels.

Maintenance Tips for Insulated Metal Panels

Regular Inspections

Regular inspections are crucial for maintaining insulated metal panels. Check for any signs of wear, damage, or corrosion. Early detection of issues can prevent more significant problems later on. Schedule inspections at least twice a year or after severe weather events to ensure the panels remain in good condition.

Cleaning Methods

Cleaning the panels helps maintain their appearance and functionality. Use mild soap and water for routine cleaning, avoiding harsh chemicals that could damage the surface. For tough stains, use a soft brush to scrub gently. Regular cleaning prevents buildup of dirt and debris, ensuring the panels look good and perform well.

Addressing Damage Promptly

If you find any damage, address it promptly. Small issues like scratches or dents can get worse if left unchecked. Repair or replace damaged panels as needed to maintain the integrity of the insulation. Quick action keeps the building safe and efficient, protecting your investment in the long term.

Insulated metal panels are a strong choice for PEMB projects due to their energy efficiency, durability, and aesthetic appeal. They come in various types, like polyurethane, polystyrene, and mineral wool panels, catering to different needs and preferences.

Proper installation and site preparation ensure these panels perform at their best. Regular maintenance like inspections, cleaning, and prompt repairs will keep them in top condition and extend their lifespan.

Choosing the right materials and following best practices during installation and maintenance will lead to a successful project. Make sure to invest time in these steps to get the most out of your insulated metal panels.

Let Alpha Labor Co. help you with all your metal building and concrete project needs. Our expertise and commitment to quality will ensure your project's success. Contact Alpha Labor Co. today and get started on your next construction venture. Together with our insulated metal panel installers, we'll build something great.