Safety/Training

Training and safety are of the utmost importance to us at Alpha Labor. We have JSA and JHA standards in place. Training our team members is ongoing and occurs regularly. Our team member’s Certifications include: Fall Protection, Aerial Lift, OSHA 10, OSHA 30, AWS Welding Certs, NCCER, and Certified Riggers. Our in-house OSHA-authorized trainer offers outreach training programs for basic hazard awareness, OSHA 10 and OSHA 30 certifications. We can help your crews be safer by teaching safety practices to your team.

🔺 The supervisor’s commitment to safety must be clearly communicated to all employees on his crew. The supervisor’s commitment to achieving a ZERO HARM workplace is communicated frequently to all employees along with the critical role each employee plays in reaching that goal.

🔺 Knowing and consistently applying Alpha Labor Co. safety policies and all applicable safety procedures and ensuring that all personnel within their area of responsibility are aware of their obligation to perform their work safely.

🔺 Conducting regular safety inspections within their area of responsibility and taking immediate corrective action on all reported or observed at-risk behaviors or unsafe conditions to see that they are corrected safely and on time.

🔺 Conducting investigations and reporting all incidents, injuries or near miss, and ensuring corrective action is taken as necessary in a timely manner.

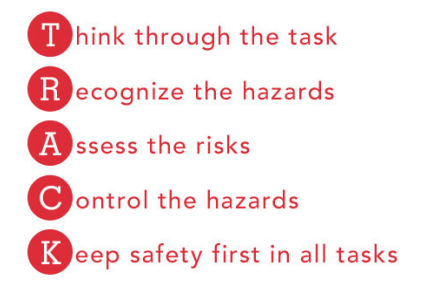

T.R.A.C.K.

Alpha Labor Co. employees utilize the Pre-Task Hazard Assessment Tool, T.R.A.C.K., before performing tasks on the job. Employees are expected to embed the five-step process into each task and to identify and correct hazards that could result in injury or incident. The five-step process is as follows:

SAFETY ACCOUNTABILITY GUIDELINES

Each supervisor is evaluated semi-annually in respect to their compliance with the Safety Accountability for Supervisors guidelines. The Safety Accountability Guidelines are as follows:

🔺 Making training recommendations as they see necessary and communicating this information to the Field Safety Supervisor or Safety Director, ensuring the proper induction of all new personnel and that they are provided with and use all protective equipment and tools required to do their jobs safely.

🔺 Holding employees accountable for careless or at-risk behavior. Employees who demonstrate this behavior will receive verbal and written guidance from the supervisor on how to correct their performance. Employees who continue demonstrating at-risk behavior by placing themselves and others at risk will be terminated.

🔺 It is critical that employees who have a high regard for safety and consistently demonstrate that commitment by following safety procedures, working injury-free, and regularly participating in safety discussions receive recognition and positive reinforcement from their supervisor. This is done publicly in safety and/or toolbox meetings.

STRETCH AND FLEX PROGRAM

Alpha Labor employees utilize a Stretch and Flex program specifically designed to meet the physical demands of each project. This program was developed under the supervision and direction of a physician specializing in occupational medicine. Alpha Labor Co. has taken a proactive approach to reducing the risk of soft tissue injuries.

QUALITY GOALS

Alpha Labor knows that quality is the result of intelligent effort.

Alpha Labor Quality Goals:

🔺 To ensure work conforms to the contract documents

🔺 To prevent construction defects from occurring

🔺 To select qualified, quality-oriented subcontractors

🔺 To perform timely inspections and tests by Alpha Labor Co., subcontractors, and third-party inspection personnel

🔺 To minimize rework during the course of construction

🔺 To ensure warranties are preserved

3 STEP QUALITY PROCESS

Alpha Labor Co. utilizes a 3-Step Quality Control Process to plan, schedule, and install work in an orderly, consistent way that minimizes costly rework.

Pre-installation Meeting: Review all applicable requirements for each activity and procedure.

Initial Inspection: Each construction activity is inspected at the commencement to ensure compliance with project requirements.

Follow-up Inspections: Follow-up inspections are performed daily and documented with a Daily Report. Upon completion of the construction activity, an Acceptance Report is generated and issued to the contractor.

Contact Us

Our Offices

Alpha Labor Co., LLC

2492 SW Racquet Club Dr.

Palm City, FL 34990

✉ info@alpha-labor-co.com