Alpha Labor takes great pride in its structural steel erectors. Our team of journeyman ironworkers are able to quickly adapt to your project’s evolving needs. Our certified JIW have extensive training to insure safety. They deliver quality work. We are able to install primary or secondary steel, interior steel, and steel framing such as mezzanines, ceiling steel, catwalks, etc.

Structural Steel Install

We are experienced in erecting metal buildings from manufacturers such as Kirby, Butler, Nucor, Varco Pruden, Chief, Metallica, Rhino, and more. Whether your project is just beginning or near completion, our crews are ready to assist in all stages of erecting metal buildings. We specialize in standing seam roof installation as well as insulated metal panel installation for both roofs and walls. We have crews who can easily and safely install primary and secondary framing on buildings, regardless of the weight.

Metal Building Erecting

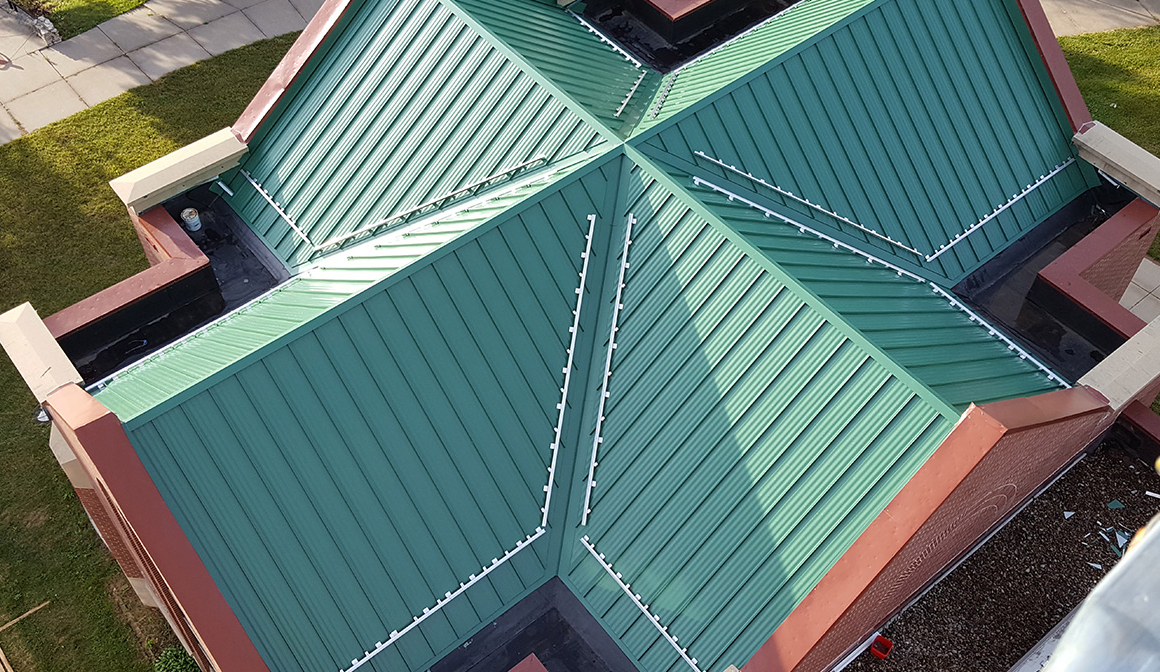

Standing Seam Roof Install

We understand that when installing a standing seam roof, a system of individual components is being installed which are related to each other, and which depend on the proper installation of each part in order for the system to perform correctly. Our installers are familiar with common accessory installations (e.g. vents, curbs, and pipe) and have installed virtually every manufacturer’s SSR; therefore, we understand the proper installation procedures which vary between manufacturer.

Insulated Metal Panel Install

Insulated metal panels are expensive! Their installation is a delicate and meticulous process. Our team understands this which is why extra thought and care are exercised when handling IMP material. Years of experience have made Alpha Labor proficient in insulated metal panel installation.

Project Management

Some projects require additional attention which is why Alpha Labor employs a team of experienced Project Managers. They can help manage onsite logistics, change orders, scheduling and production analytics. Our Project Management team are decisive, have excellent communication skills and will work with you to help achieve your goals.

Safety/Training

Training and safety are of the utmost importance to us at Alpha Labor. We have JSA and JHA standards in place. Training our team members is ongoing and occurs regularly. Our team member’s Certifications include: Fall Protection, Aerial Lift, OSHA 10, OSHA 30, AWS Welding Certs, NCCER, and Certified Riggers.

Our in-house OSHA-authorized trainer offers outreach training programs for basic hazard awareness, OSHA 10 and OSHA 30 certifications. We can help your crews be safer by teaching safety practices to your team.

TRACK

Alpha Labor Co. employees utilize the Pre-Task Hazard Assessment Tool, T.R.A.C.K., prior to performing tasks on the job. Employees are expected to embed the five-step process into each task and to identify and correct hazards that could result in injury or incident. The five-step process is as follows:

Think through the task

Recognize the hazards

Assess the risks

Control the hazards

Keep safety first in all tasks

SAFETY ACCOUNTABILITY GUIDELINES

Each supervisor is evaluated semi-annually in respect to their compliance with the Safety Accountability for Supervisors guidelines. The Safety Accountability Guidelines are as follows:

The supervisor’s personal commitment to safety is to be clearly communicated to all employees on his crew. The supervisor’s commitment of achieving a ZERO HARM workplace is communicated frequently to all employees along with the critical role each employee plays in reaching that goal.

Knowing and consistently applying Alpha Labor Co. safety policies and all applicable safety procedures, as well as ensuring that all personnel within their area of responsibility are aware of their obligation to perform their work safely.

Conducting regular safety inspections within their area of responsibility and taking immediate corrective action on all reported or observed at-risk behaviors or unsafe conditions to see that they are corrected in a safe and timely manner.

Conducting investigations and reporting all incidents, injuries or near miss, and ensuring corrective action is taken as necessary in a timely manner.

Making training recommendations as they see necessary and communicating this information on to the Field Safety Supervisor or Safety Director. Ensuring the proper induction of all new personnel and that they are provided with and use all protective equipment and tools required to safely do their job.

Holding employees accountable for careless or at-risk behavior. Employees who demonstrate this type of behavior will receive both verbal and written guidance from the supervisor on how to correct performance. Employees who continue to demonstrate at-risk behavior by placing themselves and others at-risk will be terminated.

It is critical that employees who have a high regard for safety and consistently demonstrate that commitment by following safety procedures and working injury free and regularly participate in safety discussions, receive recognition and positive reinforcement from their supervisor. This is done publicly in safety and/or toolbox box meetings.

Equipment Sales & Rental

To supplement our erecting projects, Alpha Labor sells and rents specialized pre-engineered metal building equipment such as:

Vacuum lifters for IMP roof and wall installations

Material handling systems

Magnetic drills

Lifting equipment (e.g. spreader bars, lifting slings, chain hoists, lifting clamps, etc.)

How It Works

When you’re ready to proceed, contact us with information such as:

1. Start date

2. Job location

3. Length of time workers are needed

4. Approximate number of workers needed

5. Project details

We’ll reach out to discuss your project needs. If you’re not sure how many people you need, etc., we’re happy to consult with you and answer any questions. After we review our housing costs we will provide you with a quote that includes the hourly labor rate.